Author: WECC REMTF[1]

Author: Sandia National Laboratories[2]

Grid-connected photovoltaic (PV) systems cover a wide range of applications. Most PV systems are residential (up to several kW) and commercial scale (up to several MW) connected to distribution networks. However, many PV systems are large generation facilities (some exceeding 100 MW) and are connected to the transmission system. NERC Reliability Standards require that power flow and dynamics models be provided, in accordance with regional requirements and procedures. Under the existing WECC modeling guidelines[3] all PV power plants with aggregated capacity 20 MVA or larger must be modeled explicitly in power flow and dynamics. This means that these plants must not be load-netted or modeled as negative load. Manufacturer-specific dynamic models commonly provided for interconnection studies are not adequate for regional planning. For this application, WECC requires the use of approved models, that are public (non-proprietary), are available as standard-library models, and have been tested and validated in accordance to WECC guidelines. Approved models are listed in the WECC Approved Dynamic Model List.

Contents

Architecture

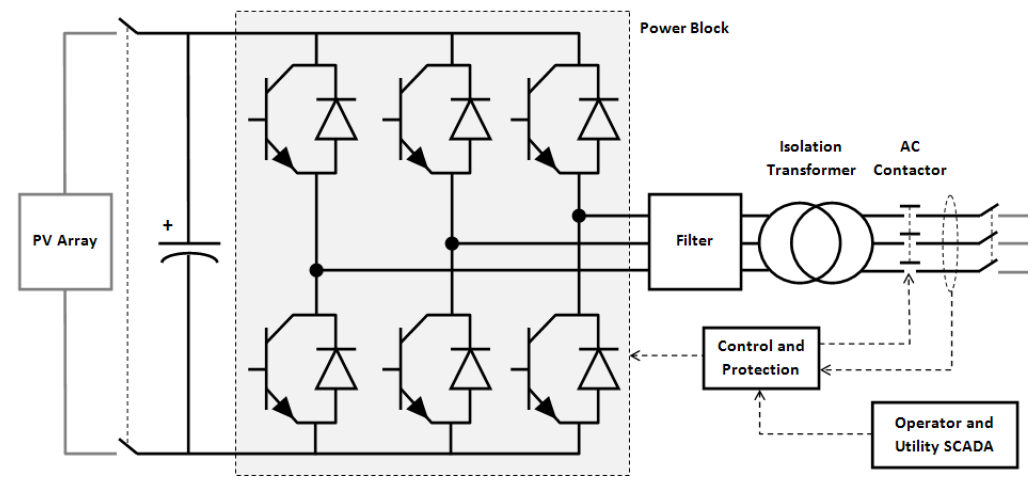

Solar power plants are different than conventional power plants. The interface to the grid is an inverter connected to a PV array. Inverters are required to transform the DC output of the solar arrays to alternating current (AC) electricity compatible with the electric grid. One of the inverter functions is to control the DC voltage to ensure that the PV array operates at maximum power. Inverters also incorporate grid compatibility functions such as anti-islanding, and reactive support.

Inverters are characterized by low short circuit current contribution, lack of mechanical inertia, and high-bandwidth (fast) controls. A primary function of the inverter controls is to make the most efficient use of available energy being produced by the PV array, while ensuring that the magnitude of AC current does not exceed the rating of the inverter. PV plants do not have any inherent inertial or frequency response capabilities.

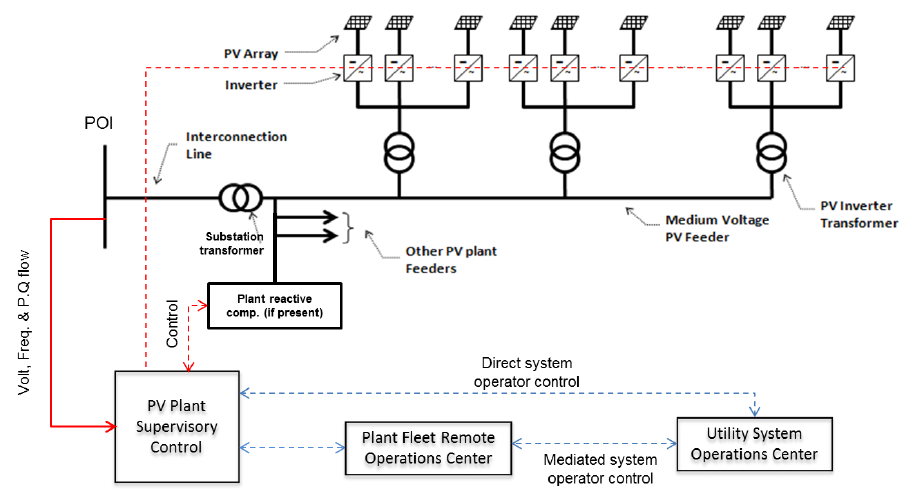

Large PV plants typically have several medium voltage radial feeders. The PV inverters are connected to the feeders via step-up transformers, with several inverters sharing one step-up transformer. Some plants designs include capacitors or other reactive support systems that work in conjunction with the inverters to meet reactive power capability and control requirements at the point of interconnection. A plant controller provides the power factor reference to the inverters and plant-level reactive power support equipment, if present. The plant controller processes measurements at the point of interconnection and commands issued from the fleet remote operations center or directly from the transmission system operator.

Small PV systems are deployed in customer premises and are connected directly to distribution service voltage. These systems do not typically have a plant controller, and the inverter manages the grid interface. Some PV systems as large as 20 MW are connected directly to distribution substations using a dedicated medium voltage feeder.

PV plants are considered non-dispatchable because the energy source (solar irradiance) is variable. However, reactive power is dispatchable within the capability of the inverters and plant-level reactive compensation.

Types of PV Arrays and Tracking Systems

Photovoltaic systems use semiconductor cells to convert solar radiation into DC electricity. The three most common types of PV technologies are crystalline silicon (c-Si), thin-film technology, and concentrating PV. Crystalline silicon solar cells are by far the most common technology for the solar cell market today[4]. Current reporting on efficiency of thin-film cells are in the area of 11% whereas c-Si cells come in around 20%[5]. Thin-film technology can also use Si as the semiconductor (usually amorphous Si) but have also used other materials such as cadmium telluride (CdTe). Concentrating PV technologies utilize lenses or mirrors to focus sunlight on a small area of highefficiency cells. Demonstrations of concentrating PV show large-scale system efficiencies of 25%[6]. In addition to the semiconductor technology, there are different ways that a system can optimize energy capture. The arrangement and angle of the PV cells can play an important role in the total energy capture of the plant. While it is more common for PV arrays to have fixed mounts, some PV arrays use one-axis tracking systems to enhance energy production.Tracking systems are required for concentrating PV.

Inverters and Other Balance of Systems

Inverters are required to transform the DC output of the solar arrays to alternating current (AC) electricity compatible with the electric grid. One of the inverter functions is to control the DC voltage to ensure that the PV array operates at maximum power. Inverters also incorporate grid compatibility functions such as anti-islanding, and reactive support.The rating of power converters for large-scale solar plants today is typically 250 kW;however,1-MW converters are just starting to appear.

References

- ↑ WECC, WECC PV Power Plant Dynamic Modeling Guide, March 2014, [Online]. Available: https://www.wecc.biz/Reliability/WECC%20Solar%20Plant%20Dynamic%20Modeling%20Guidelines.pdf. [Accessed June 2015].

- ↑ Sandia NL, Utility-Scale Photovoltaic Procedures and Interconnection Requirements, February 2012, [Online]. Available: http://energy.sandia.gov/wp/wp-content/gallery/uploads/PV_Interconnection-SAND2012-2090.pdf. [Accessed February 2013].

- ↑ WECC Data Preparation Procedural Manual for Power Flow Base Cases and Dynamic Stability Data”, WECC System Review Work Group, Approved March 27, 2013.

- ↑ For more information, see http://www.eere.energy.gov/basics/renewable_energy/photovoltaics.html.

- ↑ B. Kroposki, R. Margolis, and D. Ton; Harnessing the sun, Power and Energy Magazine, IEEE , vol. 7, no. 3, pp. 22-33, May-June 2009.

- ↑ S. Kurtz, “Opportunities and Challenges for Development of a Mature Concentrating Photovoltaic Power Industry,” National Renewable Energy Laboratory, 2009.