The planet’s current energy system based on fossil fuel–derived energy has come with unwanted environmental impacts, largely driven by emissions that impact climate and local air and water quality. As society drives toward a cleaner, more sustainable energy system, the cost improvements and scale of wind and solar energy are enabling an economically viable transition toward a more electrified energy system. Hydrogen from electrolysis is seen as a critical element to move energy across space and time to market, while simultaneously enabling clean, decarbonized end use.

Unlocking these unique attributes of hydrogen to enable the realization of its full potential will require advances in making, moving, storing, and using hydrogen, with electrolyzers filling the critical role of enabling green hydrogen production through coupling with renewable resources. The key issues will be addressing the cost, performance (efficiency), and durability of systems to enable increased economic competitiveness at the earliest opportunity.

Unlocking these unique attributes of hydrogen to enable the realization of its full potential will require advances in making, moving, storing, and using hydrogen, with electrolyzers filling the critical role of enabling green hydrogen production through coupling with renewable resources. The key issues will be addressing the cost, performance (efficiency), and durability of systems to enable increased economic competitiveness at the earliest opportunity.

Cost and Efficiency

Electrolyzer cost has decreased significantly over the past decade, but is still far too expensive to meet cost parity with fossil-derived hydrogen for most applications. The capital cost of electrolyzers has not been the primary focus of current electrolysis systems because of the high cost of electricity and the high value of hydrogen for most of the current electrolysis markets. One of the primary keys to meeting hydrogen cost targets of the future is capitalizing on low-cost electrons made available due to imbalance between grid generation and demand.

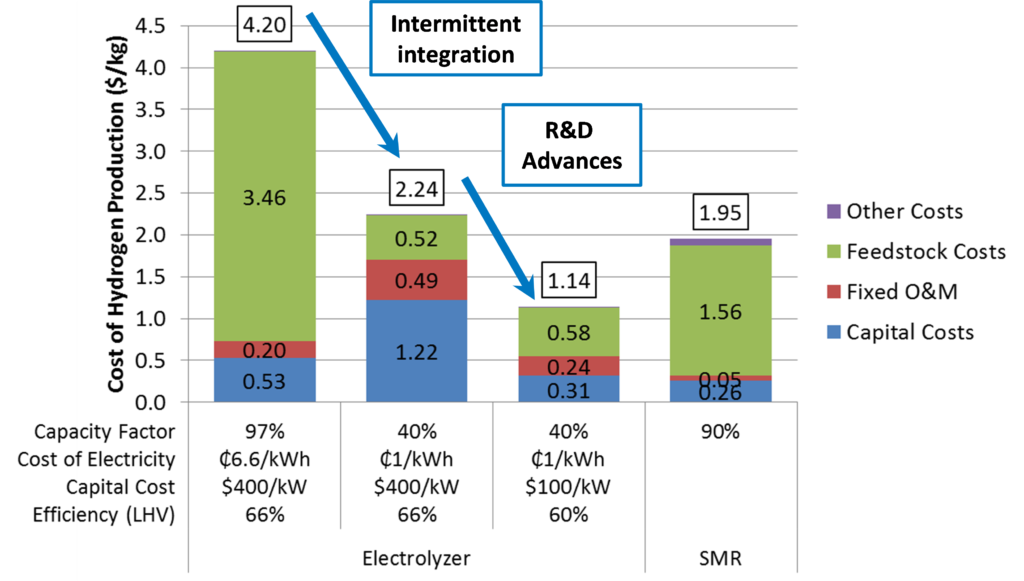

This is highlighted in the hydrogen cost trend figure below, showing the impact of electricity cost and capital cost. As low-cost electrons become available in greater quantity, electrolyzer capital costs become a central focus of economic hydrogen production. Research and development advances are then required to decrease capital costs to enable cost competitiveness with fossil-derived, steam methane reformed (SMR) hydrogen. To date, decreased capital costs haven’t been the primary concern for such systems, and these systems have therefore seen limited research investment. Fuel cells—similar electrochemical devices that run in the opposite direction, making water and power from hydrogen and oxygen rather than converting power and water into hydrogen and oxygen as electrolyzers do—have seen billions of dollars of investment over the past few decades and capital cost reductions of a larger scale than proposed here. However, while performance of these systems is also important, because the cost target of electricity is so low, efficiency isn’t as big a driver for cost as capital costs or durability.

Durability

A key concern for electrolyzers of the future and one of the primary research uncertainties is how durable these very-low capital cost systems will be under variable operating conditions representative of grid balancing operation. Research is still needed on the fundamental degradation mechanisms, potential mitigation strategies, appropriate accelerated stress tests, and system and component design aspects of electrolyzers. These topics are currently the focus of a major US Department of Energy Research Consortium, H2NEW (Hydrogen from Next-Gen Electrolyzers of Water). The focus of this effort is to determine the cost, performance, and durability tradeoffs of different electrolysis systems and operating strategies in order to enable and accelerate production of the lowest-cost hydrogen. Expectations for highly durable systems are anticipated due to the success of fuel cells in transportation applications with variable drive cycles and the durability experienced for current state-of-the-art electrolyzers. However, the impacts of decreasing capital costs and operating conditions still aren’t fully understood or appreciated.

Research Advances Needed in the Next Decade

It is clear that hydrogen is being targeted as a critical centerpiece to a clean, sustainable energy system, and that one of the first and most critical barriers to enabling economically competitive green hydrogen is electrolyzer advances. While the market today is expanding at an incredible rate, specific advances in cost, performance, and durability remain critical to achieving economic parity and a gigaton scale. The question is no longer “will green hydrogen be part of the future energy system?” but rather “how big of a role will it play?” The answer to this question and the economic impact of hydrogen will critically depend on the cost, performance, and durability advances that the technology achieves over the next decade.

Bryan Pivovar

Senior Research Fellow, Fuel Cell Group Manager

NREL

Hi, informative article. Question: assuming most of the electricity for the electrolyzer will come form wind and solar generation, for the scale of H2 use that we are thinking about (potentially 25% of the energy demand) would not hydrogen making take away from wind and solar – that is supposed to go to the grid directly to supply the decarbonized grid? Unless we assume that potential for wind and solar generation is infinite within a region (not realistic) there should be a limit for H2 generation alongside wind and solar generation for the grid. Thx.

New Solar and Wind are being purposely built to supply energy to drive Electrolyzers so the concern is diminished. Also, for existing Solar and Wind, it is preferable that excess electricity be diverted to Electrolyzers rather than injected into the grid for the sake of grid stability. For that reason I think there should be an economic benefit applied to the business case of Electrolyzer and new Solar and Wind which otherwise would have to be expended by the grids to address grid issues

Solar and wind are discontinuous by default, they obviously have a role to play in overall cost reduction! Unfortunately our World runs on baseload capacity, the amount of curtailed electricity you are discussing is minute and uneconomic. Electrolysis is not economic today unless provided with low or no cost electricity. Without a significant technology breakthrough, electrolysis will never be economically comparable to fossil fuels. At H2EG.com, we produce low cost Green Hydrogen from biomass. Completely sustainable and ultimately renewable… The future is circular, not discontinuous!

it depends on the role of of electrolyzer i suppose. if its used to use the other wise curtailed RE than the cost of electricity would be low at that time and it can result in economical fuel genration. hwoever if electrolyzer is used to supply hydrogen to industrial demands then its capacity utilization factor and electricity prices (mainly onsite generation + backup grid) would matter.

Yes I am fully convinced & agree with Headrick, there is urgent need for major technological breakthrough towards cost effective electrolyzer. This will make cheaper green hydrogen. Worldwide support/incentive is required towards this cause.