In order to combat climate change, there is a global need for deep decarbonization, and all sectors that produce carbon dioxide (CO2) must play a role. In 2019, global CO2 emissions from fossil fuels totaled ~33 gigatons, with ~41 percent coming from the power generation sector. The good news is that there are solutions available today to enable reduction of the power sector’s carbon emissions. In addition to solar, wind, and other renewable power sources, we have opportunities to reduce the carbon emissions from existing fossil fuel–based technologies, like gas turbine power plants. The importance of such a move cannot be understated, as many other industries—such as transportation and home heating—are reliant on increased electrification for carbon reduction plans, placing a greater burden on decarbonizing the power generation system itself for these moves to have tangible impact.

A systematic approach to reduce the carbon emissions from high-efficiency natural gas–based power generation involves two fundamental choices: switching to zero or net-zero carbon fuels, or the use of post-combustion carbon capture. The former approach takes advantage of the fact that gas turbines are highly fuel flexible and can operate on a range of fuels including hydrogen.

A systematic approach to reduce the carbon emissions from high-efficiency natural gas–based power generation involves two fundamental choices: switching to zero or net-zero carbon fuels, or the use of post-combustion carbon capture. The former approach takes advantage of the fact that gas turbines are highly fuel flexible and can operate on a range of fuels including hydrogen.

Decades of Experience

The gas turbine industry has been using fuels that contain hydrogen for more than 30 years, accumulating more than 17 million operating hours. Gas turbines have operated on fuels with hydrogen concentrations ranging from 5 percent (by volume) up to 100 percent. This includes the use of hydrogen / natural gas fuel blends as well as industrial fuels containing hydrogen.

One example of an industrial fuel that contains hydrogen is syngas (synthesis gas), which is typically produced by gasifying coal or refinery residue. Syngas typically has about 30 to 40 percent hydrogen (by volume). When gasification is coupled with a gas turbine, this is typically called an integrated gasification combined cycle (IGCC) plant. The first demonstration of an IGCC plant at commercial scale was in 1984 at the Cool Water Project located in California, which utilized a GE 7E gas turbine.

Other examples of industrial gases that contain hydrogen include gases produced during steel production (e.g., coke oven gas and blast furnace gas) as well as a variety of refinery and process waste gases. These fuels have been used for power generation for many years by both heavy-duty and aeroderivative gas turbines. A prime example of this category is a GE 6B gas turbine (~44 megawatts) that has operated for more than 20 years on a refinery waste gas with a hydrogen content that has varied from 70 percent to 95 percent (by volume).

In some cases, there isn’t enough of the hydrogen-containing fuel to operate the gas turbine; in these cases, the fuel can be blended with natural gas. This type of upgrade was successfully implemented nearly a decade ago on a set of 7F gas turbines in the US. In fact, as demand for hydrogen as a fuel source for power generation grows in the coming years, supplying the required hydrogen at the scale necessary is as great of a challenge—if not greater—as operating a gas turbine using the fuel itself.

Application to New and Existing Gas Turbines

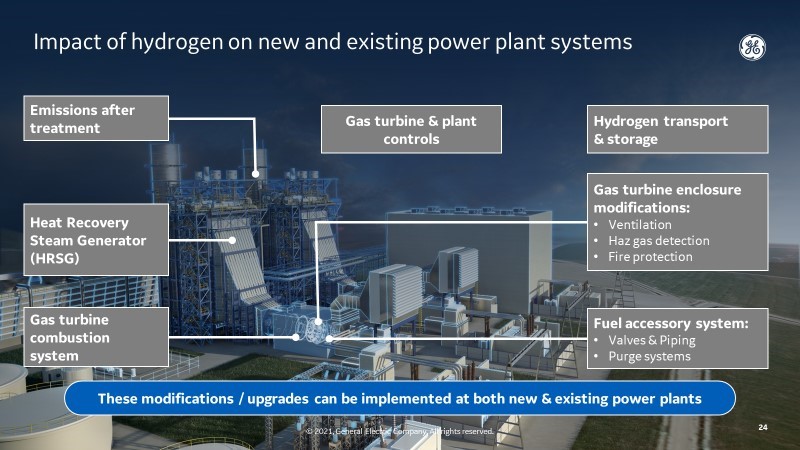

Based on these experiences, it is clear that gas turbines can operate on hydrogen and blends of hydrogen and other fuels, and a future transition to the use of hydrogen as a zero-carbon gas turbine fuel may be possible. The industry’s experience with industrial fuels provides insights into the changes or upgrades that may need to be applied to existing gas turbines as well as new gas turbines to support the use of hydrogen. For example, an existing power plant can be upgraded to operate on blends of hydrogen and natural gas. If hydrogen is being supplied separately from natural gas, this requires the addition of a new (fuel-blending) system to inject hydrogen into the existing fuel system.

New gas turbine power plants could be “hydrogen enabled,” meaning that they are configured to operate on natural gas when they enter commercial operation with provisions put into place to allow hydrogen fuel upgrades more easily in the future. A hydrogen-enabled power plant might require modifications to the plant’s configuration that are easier to implement during construction than in the future when the plant is fully operational. Examples might include different physical layouts (to allow for the addition of hydrogen fuel systems) and upgrades to safety systems.

Next Steps

The use of hydrogen as a power generation fuel is an important step in helping to provide reliable, dispatchable power with lower carbon emissions (see the white paper on Hydrogen for Power Generation, the related website on Hydrogen Fueled Gas Turbines, and the Cutting Carbon podcast). But this is just one step in this process. We need to develop the infrastructure to produce blue or green hydrogen (hydrogen produced through natural gas complemented with carbon capture or via renewable energy and electrolysis) at scale as well as providing it at a cost that will make electricity affordable for all. While challenges remain, the advancement of this critical technology capability will enhance efforts to decarbonize power generation and combat climate change.

Jeffrey Goldmeer

Emergent Technologies Director – Decarbonization

GE Gas Power

Nice blog! Do you think it would make sense to also prepare for ammonia as a fuel for gas turbines? Usually gas turbines are peak power plants and do not get so many operating hours. Storing hydrogen is a challenge, especially when its not used so much, and may be too expensive to store compared to ammonia, which is another relevant no-carbon fuel. For sure ammonia cycle has lower efficiency and an issue with NOx, but what’s the industry view on this?

Gas CC have Efficiencies over 60% net regarding Lower heating value.

What can we expect to be the top efficiency for pure hydrogen power plant?

Best Greetings Gerhard

Jeff:

I am trying to understand the capability for existing GE combustion turbines to use hydrogen for one of my clients. The confusion comes from various GE documents showing % of hydrogen that can be mixed with natural gas without modification. Is the up to 30% for a 7EA with DLN combusters on a volumetric basis, Btu basis or mass basis? I have seen documents which show this information in different ways. I attempted to contact GE through Hydrogen website and I am not getting past teh gate keeper.

Richard –

Good day. When we quote percent H2, it almost always on a volume basis. Can you reach out to me on LinkedIn? If so, I can send you my email address and I can help connect you to the approprirate person in GE.

Sincerely,

Jeffrey Goldmeer

Dears sirs, i need to study the fonctionnement if the turbines whith hydrogen. The turbines can’t explose?. Give more than complementions.