Introduction

The process for connecting large generators to the bulk electric system in the United States (U.S.) was designed in the early 2000’s. For about a decade, wind and natural gas resources had the largest share in the interconnection queues and have since then grown into mature technologies, with sophisticated plants designed by experienced engineers. As Independent System Operators (ISOs) and Regional Transmission Organizations (RTOs) developed and revised their processes and technical requirements with mostly wind generators in mind, the Federal Energy Regulatory Commission (FERC) followed suit with revisions to its large generator interconnection process (LGIP) and pro-forma interconnection agreement (LGIA). But with emerging resource technologies and new plant developers rushing to hedge the risk of limited transmission interconnection capacity, interconnection queues around the U.S. today have tripled and a backlog of more than 1,400 GW of generation and storage projects are facing multi-year study delays (see “Queued Up: Characteristics of Power Plants Seeking Transmission Interconnection”, by Lawrence Berkeley National Laboratory).

Even though only about a quarter of the projects in the queue will come online, the addition of several hundreds of Gigawatts of inverter-based resources (IBRs) each year have begun to change the dynamic performance of the U.S.’s bulk electric system. A lack of harmonized technical minimum capability and performance requirements for emerging IBRs and a lack of experienced engineering personnel are recently leading to wide-area disturbance events involving IBRs as documented by the North American Electric Reliability Corporation (NERC). These events are putting reliability of the bulk power system at risk. Concerned stakeholders see the U.S. on a trajectory to repeat mistakes like those that were ultimately resolved by European governments with major retrofit programs for legacy wind and solar plants during the early 2010’s.

Why is the North American Interconnection Process Broken?

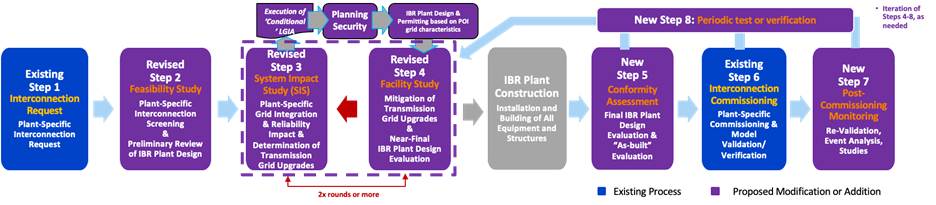

Figure 1 shows the current FERC Large Generator Interconnection Process (LGIP). With some exceptions, ISOs/RTOs move a new resource serially through the process on a first-come, first-served basis. Often developers submit multiple interconnection requests to reserve a queue position irrespective of a developer’s commitment to eventually build a plant. Even for those projects that do move ahead, the studies required by the LGIP occur so early in the process that the models used throughout the process are seldom informed by selected equipment or the final plant design. The lack for harmonized technical requirements leads to uncertainty in plant performance. The formal LGIP becomes more about “checking off boxes” than “getting it right.” A process intended to ensure reliable connection of large generators to the BPS, at times revolves more around financial risk management than fostering open and frequent communication and technical coordination between the involved parties.

FIGURE 1

Existing Interconnection Procedure as shaped by the FERC Large Generator Interconnection Process

Source: Workshop presentation by J. Boemer, Electric Power Research Institute.

Further aggravating these challenges IBR facility’s control parameters often change at the time of plant commissioning. This can lead to performance different from what was studied throughout the interconnection process, a potentially risky reliability gap if not reconciled afterwards. With no formalized conformity assessment prior to or around the commercial operation date required by either FERC LGIP or NERC reliability standards, verification that the capabilities and performance of a new plant meet all applicable technical requirements is a rare practice.

Limited requirements and practices for collection, storage, and analysis of high-resolution plant performance data have obscured insidious BPS reliability impacts from recently connected large solar plants. Lack of field data is further hindering plant model validation and continuous verification of plant performance during operation.

The named deficiencies make existing interconnection processes across the U.S. unnecessarily lengthy and backlogged, with studies varying significantly in terms of assumptions, scope, and modeling rigor. Many of these processes fail to ensure streamlined and reliable interconnection of IBRs.

Interconnection Process Reform Informed by International Leading Practices

Informed by international leading practices from Europe and Australia, stakeholders represented in NERC’s Inverter-based Resource Performance Subcommittee, ESIG’s Reliability Working Group, and IEEE SA’s P2800.2 Working Group, increasingly support the following broad recommendations that strive to improve the interconnection processes in the U.S. by adequately balancing process efficiency with effective reliability and conformity assessments:

-

- A paradigm shift is needed toward IBRs pro-actively integrating a unified minimum set of The IEEE 2800 standard should be uniformly adopted by ISOs/RTOs as soon as possible, with additional interim guidance on conformity assessment before IEEE 2800.2 is available. Setting clear performance expectations for all new IBRs could expedite interconnection and improve reliability.

- All ISOs/RTOs should establish a first-ready, first-served cluster study process. All projects in a cluster should have increased financial commitments and readiness requirements to justify allocation of engineering resources. Substantive changes in the technical design of plants inside a cluster should trigger re-study of the cluster to inform reliability assessment, but not a loss of queue position.

- The FERC LGIP and ISO/RTO interconnection processes should be expanded in scope to explicitly include transmission service provider plant-level performance conformity assessment and verification before and after commissioning to ensure continuous reliable plant operation.

- Sufficiently detailed modeling should be required throughout the facility design and interconnection processes with adequate verification of model and plant control parameters. Collaboration should be encouraged between resource owner and ISO/RTO such that model, design, and control parameter updates can be openly discussed and studied without the risk of delays.

- Education should be provided, and collaboration facilitated for continual improvements of performance requirements, plant-level modeling, and model All stakeholders should engage in the development of IEEE 2800.2.

FIGURE 2

Recommended Improvements to the Interconnection Process

Source: Workshop presentation by J. Boemer, Electric Power Research Institute with additional step 5 (conformity assessment).

Next Steps

FERC issued two notices of proposed rulemaking in 2022 to address some of the identified challenges—“Improvements to Generator Interconnection Procedures and Agreements” and “to direct NERC to develop reliability standards for IBRs that cover data sharing, model validation, planning and operational studies, and performance requirements” with comments to the latter due in early 2023.

With the new IEEE 2800 standard for “Interconnection and Interoperability of Inverter-Based Resources Interconnecting with Associated Transmission Electric Power Systems” published in 2022, ISOs/RTOs and other authorities governing interconnection requirements are on their way to adopt the standard, initially with exceptions that could later be removed to achieve full adoption.

Meanwhile, the U.S. Department of Energy launched the Interconnection Innovation e-Xchange (i2X) initiative that convenes diverse stakeholders to facilitate peer-learning and inspire new interconnection ideas and capabilities.

Some experts suggest the U.S. is trailing behind other regions around the world in reforming the interconnection process for large generating and storage facilities. There is certainly great momentum in the direction of reform, and a wealth of opportunities are laying ahead of us.

Jens Boemer, EPRI

Alex Shattuck, NERC

Julia Matevosyan, ESIG

Leave a Reply